Quis nostrud exercitation ullamco

Rotary table punch die number (pr.) 41;

Max. tabletting pressing (kN) 80 ;

Max. tablet diameter (mm) Ф13 Max. tablet thickness (mm) 6 ; Max. filling depth (mm) 15;

Max. tabletting productivity (10,000 pc/h) 24.3;

Rotary speed of rotary table (turns/min) 45 ;

Working paragraphy radial (mm) Ф460 Punch die diameter (mm) Ф26 ; Punch die height (mm) 22 Upper & lower punch rod diameter (mm) Ф22;

Upper & lower punch rod length (mm) 115 ; Main motor power (kW) 4 ;

External dimension of machine (length×width×height) (mm) 1120×1180×1650 ;

Net wt. Machine (kg) 2000

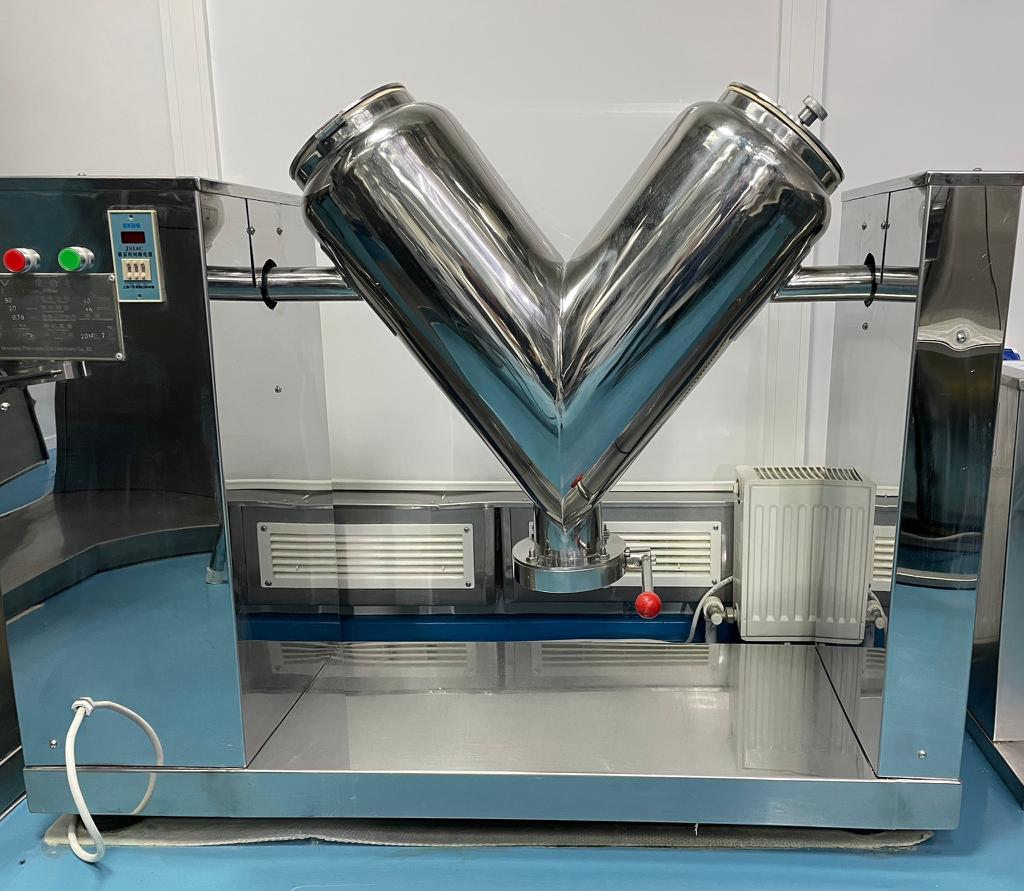

Mixer 1.

Specification (m3) – 0.05 ;

Capacity (L) – 20 ;

Rotor speed (r.p.m) – 15 ; Power (kw) 0.75 ;

Overall dimensions (mm) - 1080*520*950 ;

Net weight (kg) – 100 ;

Mixer 2.

Specification (m3) – 0.3 ;

Capacity (L) – 120 ;

Rotor speed (r.p.m) – 15 ;

Power (kw) 2.2 ;

Overall dimensions (mm) - 2100*1600*2400;

Net weight (kg) – 300 ;

Ampoules Machine, filling and sealing.

Bottle size: 1ml、2ml、irregular shape bottle ;

Yield:180-200bottle/min ;

Sealing gas-fire:a、coal gas + oxygen b、fluidity gas + oxygen ;

Gas-fire pressure:P coal gas 0.9~1Kpa Pr oxygen 0.08~0.1Mpa ;

Huff pressure:adopt no oil compressed air , pressure≥0.4~0.5Mpa ;

Motor: model:JW7134; power:0.75KW ;

Overall size (L×B×H): 2300×980×1350mm 9、weight: 560Kg ;

Oven.

Dry quantity kg/every time – 15 kg ;

Power KW – 0.75 ;

Oven plate(pcs) – 6 ;

Drying quantity (kg/time): 15 ;

Size (L*W*H) (mm) 1550*1000*2044 ;

Labeling Machine.

Labeling Speed - 100-250 bottles/minute (according to the specification, shape ofbottle and length of label) ;

Bottles size - bottle with regular shapes 1-10ml Ampoule ;

Total Power:280W; Voltage:220V;1 Phase Frequency:50HZ ; Specification of label reel: OD ≤300 mm, ID of Reel 76 mmMax Width of Labeler (including background leaf) ≤ 90 mm ;

Working temperature: 5~35°C ;

Working humidity 30%~80%, No clotted dew ;

Working environment: No flammable and explosive gas & dust ; Size:1600mm×600mm×1450 mm (Length × Width × Height) ; Net Weight: 180kg ;

Blister machine.

Punching Frequency (standard sheet80x57) imes/min - 6-50,if travel range>80mm, blister depth > 10mm , or alu/alu packing,the punching frequency can not reach 50 times/min;

Power: three-phase, four - 380V/50Hz line;

Max. Productive Capacity (thousand/h) - ALU/ALU:100 , ALU/PVC:300;

Adjustable Travel Range - 40-160 mm;

Max. Forming Area - 240×150 mm<;/dd>

Max. Forming Depth - ALU/ALU: 14, ALU/PVC:26;

Common sheet 4 plates/time - 80×57 mm;

OverallDimensions(L*W * H) - 3000×730×1600 mm

Semi-automatic blister machine.

Cutting Frequency : 5-40 (Times/min) ;

Production Capacity(pieces/h) : 30 000- 100 000 ;

Max. Forming Area And Depth (mm) : 140*100*26(mm);

Travel Range (mm): 20-120 (Standard Depth 14mm) ;

Air Pressure (Mpa): 0.6-0.8 ;

Air Supply : ≥0.2m3/min ;

Total Power: 380V/220V 50Hz 3.2Kw ;

Main Motor Power (KW): 3.2Kw ;

PVC Hard Pieces (mm): 0.15-0.5*140 (mm) ;

PTP Aluminum Foil (mm) : 0.02-0.035*140 (mm)

Washing, sterilizing, filling and sealing machine.

Warping ultrasonic bottle washing machine

Suitable bottleSuitable bottle (2ml、3ml、5ml、10ml,100ml );

Capacity:200 bottle per min (2-10ml) ;

Capacity:60-70 bottle per min (100ml) ;

Purified water consumption:0.8m3/h ;

Pressure:0.2~0.25MPa ;

Purification of compressed air consumption:36m3/h ;

Pressure:0.2~0.25MPaUltrasonic power:2Kw ;

Heating power:10Kw ;

Pass rate of washing bottle 100%Break rate:≤1 %;

Overall Size:About 2500×1200×1500 ;

High temperature sterilizing tunnel oven

Capacity:200 bottle per min (2-10ml) ; 60-70 bottles per min (100ml);

Suitable:All kinds of glass bottle ;

Heating type:Stainless steel heating tube, principle of hot air circulation;

Circulating fan:3sets;

Mesh belt width:700mm Temperature range:50~350°C;

Effective sterilization time:More than 10 minutes in the hot zone;

Exhaust air rate:5000m3/h;

Wind pressure:180~320Pa(Exhaust fan user matching);

Power supply:380V 50Hz 3phase;

Power:45Kw;

Overall size:5000×1400×1850mm;

Filling & sealing Machine

Production ability: 50~60 bottle/min ;

Applied bottle:30~500ml;plastic or glass bottle;

Sealing rate:≥99% ;

Seal way: Turns on lathe covers ,grips covers or spiral twists the lid ;

Power supply:380V 50Hz Three-phrase four-wire ;

Power:2 Kw ;

MICRONIZATOR (PLANETARY BALL MILL SERIES)

Output (kg/h): 1 - 1.96 kg/h ;

Output Size (mesh):400 - 12500 mesh ;

Range of Spindle Speed(r.p.m):70 - 670 r.p.m ;

Max capacity:1.98L ;

Rotation speed:70-670 rpm ;

Power supply:220V/110V ;

Feeding size: Less than 10mm ;

Power:0.75KW ;

Final particle size:Down to 0.1um ;

Feeding Size (mm):0.1 - 10 mm ;

Power (kW):0.75 ;

Dimension(L*W*H):750*470*564mm ;

Sealing and filling machine (semi-automatic).

Automatic Grade: Semi-automatic ;

Packaging Type: Bottles ;

Bottle Capping Height: 35-300mm (Adjustable) ;

Bottle Capping Speed: 20-25 bottles/ min ;

Packaging Material: Metal, Glass, Ropp capping machine ;

Packaging Type:Bottles ;

×